The world is facing devastation caused by plastic waste. Approximately 60% of 80,000 metric tonnes of plastic ever made is no longer in use by humankind and is instead either utilized as landfill or is released into the environment. If calculated on the basis of contribution per individual living on the planet, it amounts to about 400 kg1. Once plastic materials are discarded into the environment, they end up in landfills or oceans because degrading them at ambient temperatures is difficult and they require decades to decompose. Hence, reduction, reuse and recycling are the three pillars of sustainable development that can help save the environment.

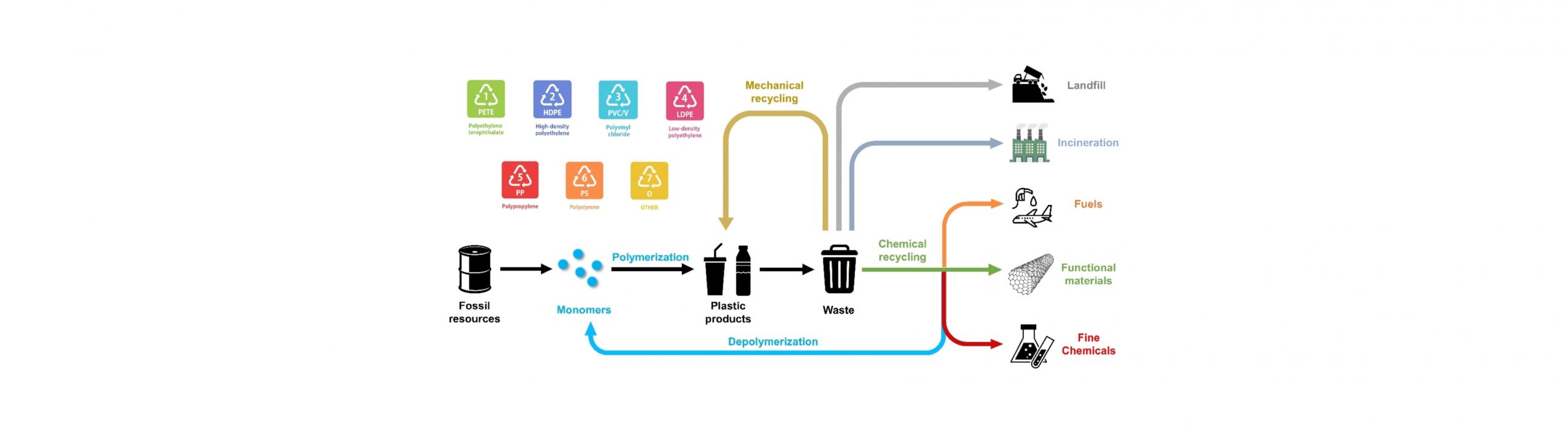

In Europe, about 30 million tonnes of plastic waste is collected every year. Still, 85% of that is incinerated, exported or sent to landfill. This is not only a source of CO2 emissions but is also a waste of valuable resources. The chemical industry is determined to change this. How? With chemical recycling technologies, the industry has developed complementary solutions to existing mechanical recycling to recycle mixed or contaminated plastic waste that otherwise would be incinerated or sent to landfill. These technologies can break down plastics and transform them into valuable secondary raw materials to produce new chemicals and plastics with the same quality as those made from fossil resources. Together with value chain partners, the chemical industry has already successfully developed consumer products like food packaging, refrigerator parts, mattresses, carpets, and dashboards in cars. As a next step, after having demonstrated the technologies’ viability, the industry plans to roll out the technologies at industrial scale.

WHAT IS RECYCLING?

Recycling is the method used to convert the waste materials into products which can be reused. Recycling is a key component of modern waste reduction and is the third component of the “Reduce, Reuse, and Recycle” waste hierarchy.