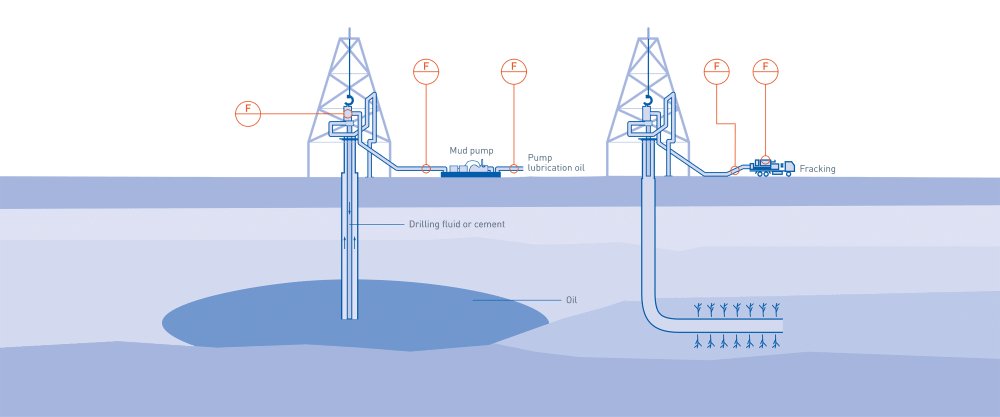

It is the process used by the drilling companies to increase the amount of oil and gas that is produced from each well. Hydraulic fracturing can be defined as the widening of fractures in a rock layer caused by high pressure injection of chemicals with water. It widens or creates fractures to speed up the migration of gas and petroleum from source rocks to reservoir.

When do you fracture?

Fracturing is done after the well has been drilled into the formation. A fluid consisting of water, proppants (is a solid material, typically treated sand or man-made ceramic materials, designed to keep an induced hydraulic fracture open, during or following a fracturing treatment) and chemicals injected into the well at extremely high pressures until eventually the rock, clay, compacted sand, or coal fractures move apart. During the extraction process, the fracturing fluid, along with any water present in the rocks before fracturing are partially removed with the oil and gas.

Hydraulic Fracking for Different Types of Wells

The pressure, flow rate, and composition of fracking fluids used for hydraulic fracking will vary from well to well. Wells might be classified according to one of the following criteria:

Vertical Versus Horizontal Wells

Vertical Wells – Verticals wells are the traditional type of oil or gas well that go straight down, typically to a depth of about 50-300 feet. These wells penetrate perpendicular to the rock layer containing the oil or gas reserve. Hydraulic fracking on vertical wells is commonly used for “well stimulation” to increase the efficiency and output of the well. Compared to horizontal well fracking, this type of fracking requires lower pressure and volume.

Horizontal Wells – Horizontal wells terminate with the wellbore parallel to the rock layer containing the oil or gas reserve. Horizontal wells also reach a much deeper depth than vertical wells. For example, horizontal wells drilled in the Barnett Shale Basin in Texas goes down between about 1,500 to 5,000 feet, while the horizontal wells drilled in the Bakken Shale Formation in North Dakota go down to up to 10,000 feet. Due to the higher pressure associated with these depths hydraulic fracking must be done at a much higher pressure and volume.

High-Rate Versus High-Viscosity Fracking – Fracking may also be done using either a high rate of pumping to deliver the proppant or a high-viscosity slurry. Each fracking method will yield slightly different results.

High-Rate Fracking – High-rate fracking uses a high rate of pumping to deliver the proppant. This is the type of fracking associated with slick water fracking fluids because the reduced friction allows the fluids to be pumped more quickly, at a higher rate. This type of fracking generally causes a network of small, spread out micro-fractures.

High-Viscosity Fracking – High-viscosity fracking uses higher fluid viscosity as its means of effectively the proppant. High-viscosity fracturing tends to be characterized by larger, more dominant fractures.

REASONS FOR HYDRAULIC FRACTURING

Hydraulic fracking offers several advantages for oil and gas recovery including:

Increased Accessibility – Hydraulic fracking offers a huge benefit by radically increasing the amount of oil and gas that can be extracted from deep-level rock formations. In most cases it would not be economic or even feasible to recover the oil and gas found in these very deep formations with extremely low natural permeability.

Greater Efficiency – As discussed above, hydraulic fracking can be used to stimulate and improve well production. This allows the oil or gas to be recovered more efficiently and at higher rates.

Lower Costs – Due to the advantages of greater accessibility and efficiency, hydraulic fracking also creates an overall better economy for the oil and gas industry, allowing companies to reap greater amounts of product at lower costs, continue operating a well for longer, or even re-open a well that may have previously been considered dried up.