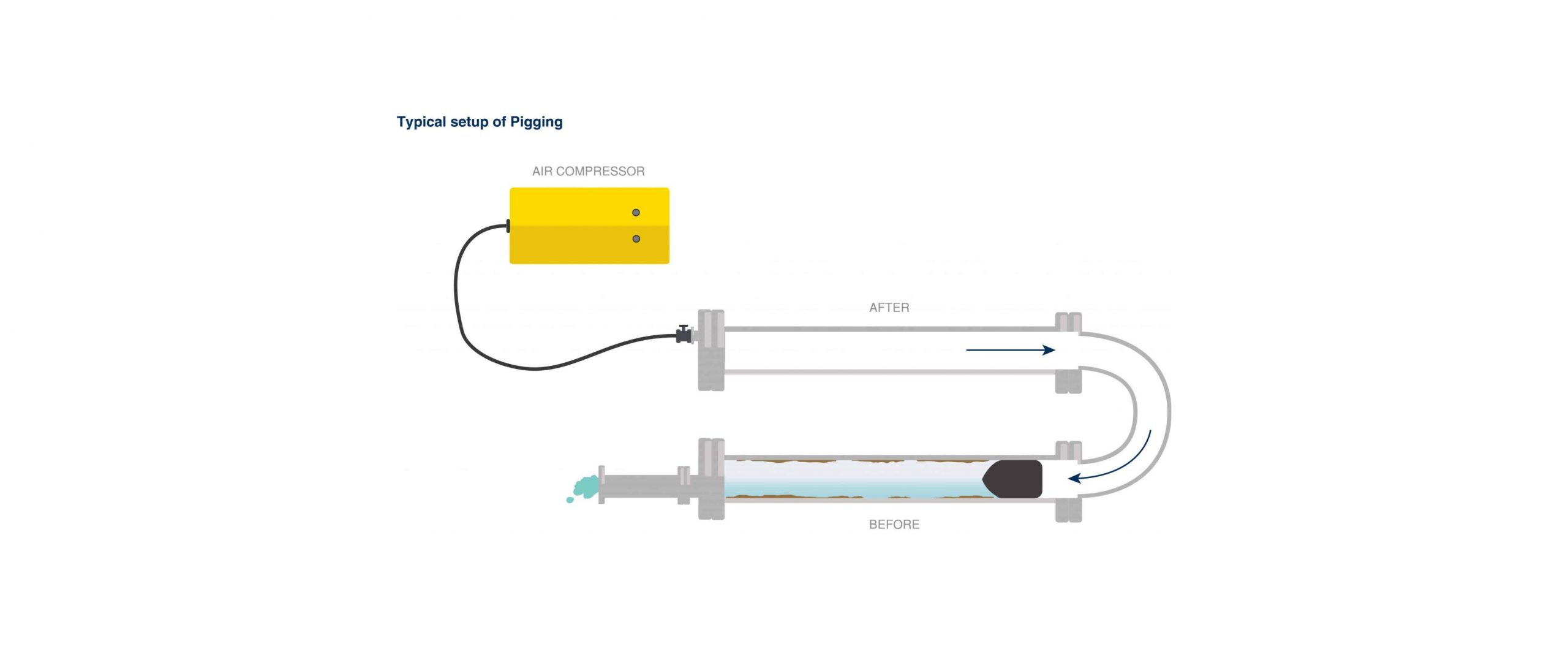

Pigging refers to a technique of cleaning or inspection of pipeline through recovering trapped products in the pipelines without stopping operation. It is done through inserting a device known as pigging pigs into the process pipelines. Pigging has been used for many years to clean large diameter pipelines in the oil industry.

The operations have been practiced for many years in the oil industry to clean big hollow pipelines. Now it is also used for cleaning smaller diameters with increased efficiencies and reduced costs.

Today, however, the use of smaller diameter pigging systems is now increasing in many continuous and batch process plants as plant operators search for increased efficiencies and reduced costs. Pigging can be used for almost any section of the transfer process between, for example, blending, storage or filling systems. Pigging systems are already installed in industries handling products as diverse as lubricating oils, paints, chemicals, toiletries, cosmetics and foodstuffs.

Industry research estimates that 40% of the world’s pipelines are difficult to pig, or otherwise deemed ‘unpiggable’. Unpiggable pipelines represent a significant challenge in the Oil and Gas Industry in relation to corrosion mitigation, flow assurance and inspection.

In many cases, there was no consideration given to the requirement for pigging at the pipeline design stage, or it was perhaps not deemed necessary based upon the understanding of fluid characteristics and/or operating conditions at the time. In some cases, pigging facilities may have been removed from the project scope due to budget constraints without due consideration given to the implications. In other cases, a pipeline may be designed to be pig gable but subsequent pipeline damage, modifications or changes in operating conditions inhibit the ability to pig.

When operators are faced with unpiggable pipelines, it is generally necessary to address the following questions:

- What is the requirement for pigging?

- Why is the pipeline unpiggable?

- Can the pipeline be made piggable?

- How and when to Pig?

- What are the alternatives to pigging?

PIPELINE PIG TYPES

Three categories of pigs are used to accomplish the above-mentioned tasks. They are:

- Utility Pigs, which are used to perform functions such as cleaning, separating, or dewatering.

- In-Line Inspection Pigs: They provide information on the line condition along with the extent and location of any problems.

- Gel Pigs, which are used in conjunction with conventional pigs to optimize pipeline dewatering, cleaning, and drying tasks.